About Rich Tech

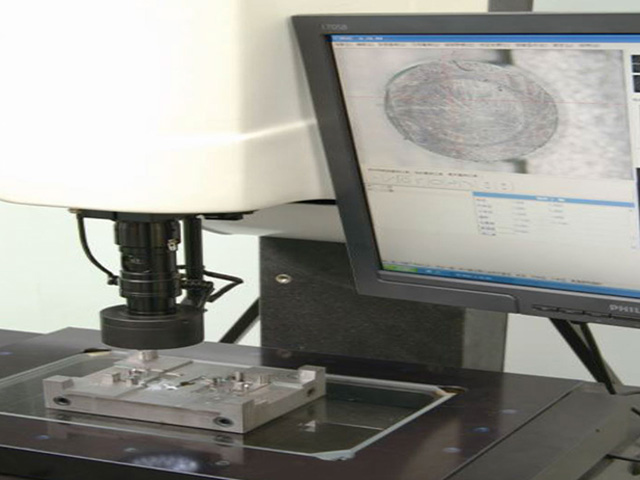

Main Equipments

CNC mahining centers: We have total 9 sets CNC Machines which include 3-Axis and 4-Axis machining centersto supply 4-Axis machining with High precision ± 0.005mm

EDM Mahine: We have total 12 sets EDM Machines precision could be 0.01mm and 0.005m for high precision requirement.

Wire walking machines: We have total 8 wire cut machines with precision ± 0.005mm

Wire walking machines: We have total 8 wire cut machines with precision ± 0.005mm

Finishing

• Paint finishing

• Powder Coating

• Chemical Polishing

• Zinc-Plating, Nickel Plating, Gold Plating

• Anodizing.

• Heat Treatment

• Ultrasonic Cleaning

• De-burring

• Powder Coating

• Chemical Polishing

• Zinc-Plating, Nickel Plating, Gold Plating

• Anodizing.

• Heat Treatment

• Ultrasonic Cleaning

• De-burring

Secondary Services

• Rapid prototyping

• Machining

• Drilling & Tapping

• Insert & Over Molding

• Assembly & Sub-Assembly

• Packaging & Labeling

• Shipping arrangement

• Machining

• Drilling & Tapping

• Insert & Over Molding

• Assembly & Sub-Assembly

• Packaging & Labeling

• Shipping arrangement

Why Choose Us

Experienced Team

All of the engineers have worked in the relative field for 10+ years.

One-stop Solution

We offer top-notch services that encompass all aspects of manufacturing,from prototyping to production under one roof

Competitive Cost

To manufacture different type of parts with the most suitable material and the right production process can save cost for you.

Strict production process control

In the production process, we strictly control the factors that affect the quality. Our control documents include the following:

1.Working Instruction

2.Official Released Drawing

3.Tool,Fixtures Change-over Record

4.Machine Maintenance Record

5.In-process Quality Control

1.Working Instruction

2.Official Released Drawing

3.Tool,Fixtures Change-over Record

4.Machine Maintenance Record

5.In-process Quality Control

Quality Assurance

Rich Technology is able to provide the raw material certificate or the raw inspection data gathered from the original inspection report per customer’s request; Inspection data including IQC, IPQC, FQC, & OQC inspection data and all other related certifications are available for a minimum of 7 years on a per lot basis.

J-I-T Delivery

Just-in-time delivery is guaranteed.What our customers care about is what we care about most