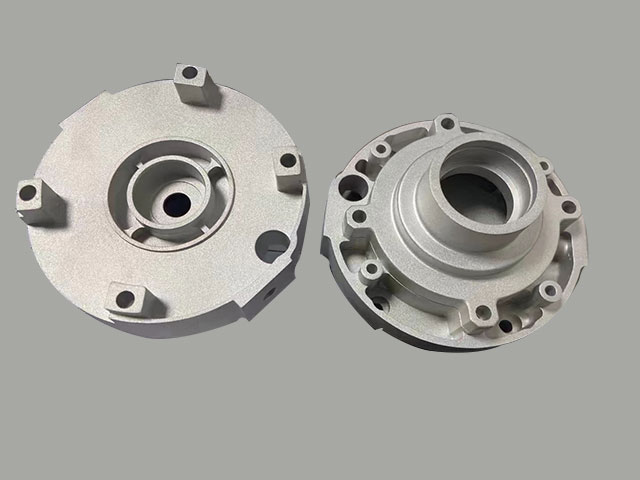

The CNC Machining process is used best for small to large production parts where parts require consistency, accuracy, and repeatability. CNC machining is a prevalent manufacturing process, often referred to as subtractive manufacturing, because it removes material to create a part using high-speed spindles and cutters. Material typically comes in sheets, blocks, bars, tubes, and rods for metal and plastic. Machining is also a commonly used process in secondary operations to take a molded or cast part from a near-net shape to the final piece to achieve tight tolerance and repeatable part accuracy.

For engineers, product developers, or designers requiring prototyping and low-volume production, Rich Technology’s custom CNC services is the solution.

CNC machining Services like CNC turning, CNC milling, CNC machining and CNC turn-milling service.

Outside Diameter is 360mm max.

Suitable to manufacture parts in round shape with high precision tolerance. High-efficiency CNC turning service.

Outside Diameter is 46mm max.

We have 5-Axis & 6-Axis TSUGAMI machines to make complex CNC turn-milling parts and save cost for you.

Workable size: 600×300×400mm

Suitable to make parts not in round shape.

Adodizing,

Electroplating,

Polishing,

Powder Coating,

Brushing,

Painting,

Black Oxide.

No tooling

Part consistency and repeatability

Part accuracy

Wide range of materials

Plastics and metals